Water Bottling Business Update

The equipment ordered from China has been received. Due to the impact of the Pandemic, work is progressing slowly but steadily as they coordinate remotely with the Chines firm. Fortunate, Paul found an experienced local contractor, Hydromasters Limited, who is able to provide services.

Paul and the team have some very good progress especially on the electricals and ensuring all the machines are hooked up to power outlets. Also, the plumbing works from the RO room into the water factory and to individual machines have been completed. The compressors have also been positioned in their space and the piping is done into all the specific

machines that need air. The goal of the local engineer was to test the machines especially at the stage of filling and capping for all the bottles, that is, 500ml, 1litre machine, 5litre machine, and the 5gallon machine. Each of these three machines have a line with several other components/machines to the end product which is a filled, capped, dated, sticker put on and where necessary wrapped. Right now they have not moved to the other machines as we got stuck at the testing of the 5-gallon machine.

The testing of the 500ml machine went fine, and you can find a test run video attached. When we came to the 5gallon machine the engineer got stuck since it could not fill the two 5 gallon bottles in

time to push to the capping stage. The engineer thought it was a pressure issue but has since ruled out that after bringing over a pump along the line and still the two bottles could not get filled up in

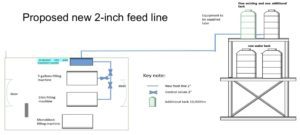

time. Now the focus is on the pumps which supply the water to the machines. The entry to the pumps of both machines is 2 inch and the engineers had reduced that to half-inch pipes. Now the challenge is to introduce two-inch pipes to supply to the 5-gallon and 5-litre machines. The engineer has submitted a plan which includes a new 2-inch feed line and tank as shown below.

The delivery truck has been ordered with funds from the matching grant. As with the equipment installation, the pandemic has affected delivery times so Paul is unsure yet when they will take delivery of the vehicle.